Better Silver’s Competitive Strategies

Responding promptly to the demands of a continually evolving market is one of the challenges that Better Silver has won. Paolo Bettinardi explains the innovative strategy that the leading silver chain and jewelry manufacturing company has implemented

What makes a company competitive these days? We spoke with Paolo and Andrea Bettinardi, directors, together with their father Romano, of Better Silver, which continues to invest in new technologies to shorten the supply chain, make product traceability more transparent and offer their customers maximum confidentiality and quality.

Better Silver is one of the silver sector’s leading partners.

What is the key to this success?

One of the things that makes out company stand out is our technological drive. Our investments have always been channeled with a view to integrating the entire production process within our factories: an objective we have been pursuing for years.

What are the advantages of such a verticalized process?

Being able to produce almost exclusively on our own premises not only allows us to offer greater product traceability transparency but also guarantees quality, confidentiality and speed. This is particularly appreciated by the big players in fashion and jewelry that want items to be quickly monitored throughout every phase and with considerable manufacturing capacity. Offering a short supply chain is a real advantage for us and is the reason why we are constantly ready to invest in integrating new processing phases, including the most marginal.

What are your most important in-house phases?

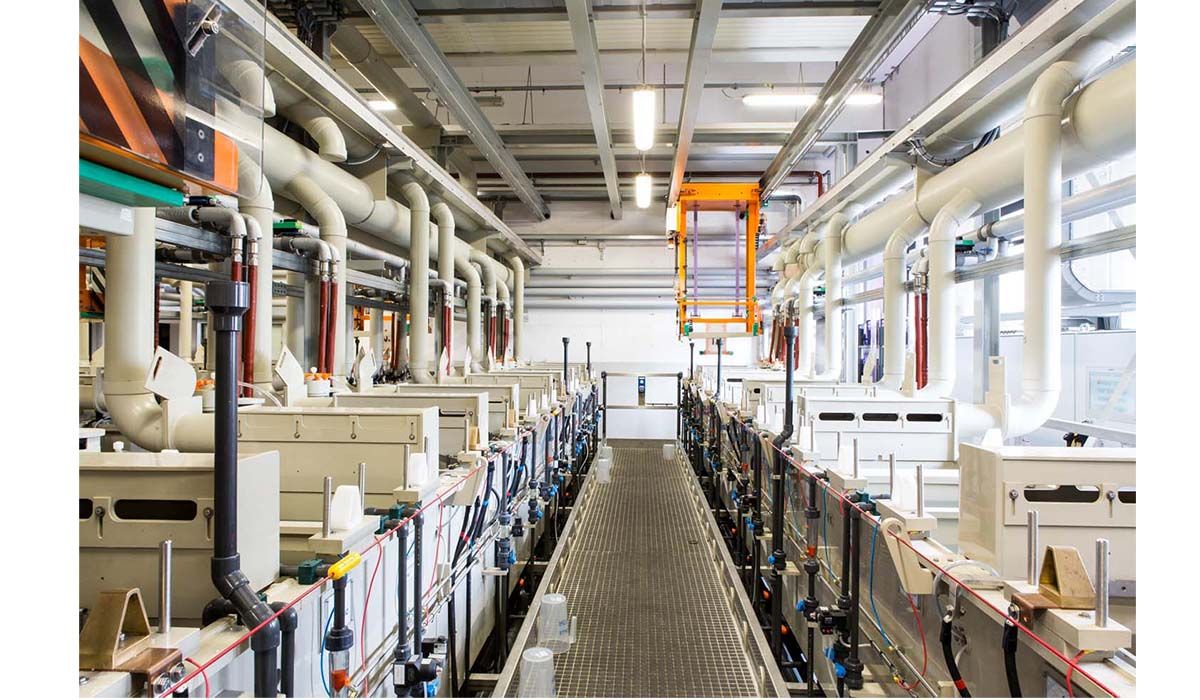

Making silver chains, even simple ones, requires a series of steps, one after the other, that we do in-house. We start from smelting the sheet metal and wire and, through a production system that develops over about 15 phases and 13,000 square meters, we can take it as far as the plating stage, the process that gives the product its final look. Transforming the wire and sheet metal into chain is an essential step that we do in a department that has about 700 machines. This means that we have enormous manufacturing capacity and can closely supervise the various technical dynamics. Then there are further steps like those that give the chain resilience. Welding, for example, or “diamond polishing” which enhances the silver and makes the surface of the chain shine.

What is the innovative part you are most proud of?

We are proud of being extremely open minded. Our path is crossed by input coming in from other sectors, from fashion as well as the world of eyewear and even metallurgy. This enriches our knowledge and determines the company’s industrial manufacturing heritage.

Can you give us an example?

We are known for producing very particular chains, like tennis chain, for example, with embedded stones. Moreover, managing to constantly integrate new products and expand our production capacity makes us extremely reactive. In this respect, we have almost finished building a new production unit of about 2,500 m² which will house new investments to further extend our process.

The great challenge is to respond promptly to a rapidly evolving market with products that are always state-of-the-art.

Better Silver is one of the silver sector’s leading partners.

What is the key to this success?

One of the things that makes out company stand out is our technological drive. Our investments have always been channeled with a view to integrating the entire production process within our factories: an objective we have been pursuing for years.

What are the advantages of such a verticalized process?

Being able to produce almost exclusively on our own premises not only allows us to offer greater product traceability transparency but also guarantees quality, confidentiality and speed. This is particularly appreciated by the big players in fashion and jewelry that want items to be quickly monitored throughout every phase and with considerable manufacturing capacity. Offering a short supply chain is a real advantage for us and is the reason why we are constantly ready to invest in integrating new processing phases, including the most marginal.

What are your most important in-house phases?

Making silver chains, even simple ones, requires a series of steps, one after the other, that we do in-house. We start from smelting the sheet metal and wire and, through a production system that develops over about 15 phases and 13,000 square meters, we can take it as far as the plating stage, the process that gives the product its final look. Transforming the wire and sheet metal into chain is an essential step that we do in a department that has about 700 machines. This means that we have enormous manufacturing capacity and can closely supervise the various technical dynamics. Then there are further steps like those that give the chain resilience. Welding, for example, or “diamond polishing” which enhances the silver and makes the surface of the chain shine.

What is the innovative part you are most proud of?

We are proud of being extremely open minded. Our path is crossed by input coming in from other sectors, from fashion as well as the world of eyewear and even metallurgy. This enriches our knowledge and determines the company’s industrial manufacturing heritage.

Can you give us an example?

We are known for producing very particular chains, like tennis chain, for example, with embedded stones. Moreover, managing to constantly integrate new products and expand our production capacity makes us extremely reactive. In this respect, we have almost finished building a new production unit of about 2,500 m² which will house new investments to further extend our process.

The great challenge is to respond promptly to a rapidly evolving market with products that are always state-of-the-art.