Cutting-edge Technologies for the Workshop

“Simulating the casting process for jewelry making.” This is to be the topic of the talk given by Vera Benincasa, process engineer for Mattioli S.p.A., at JTF

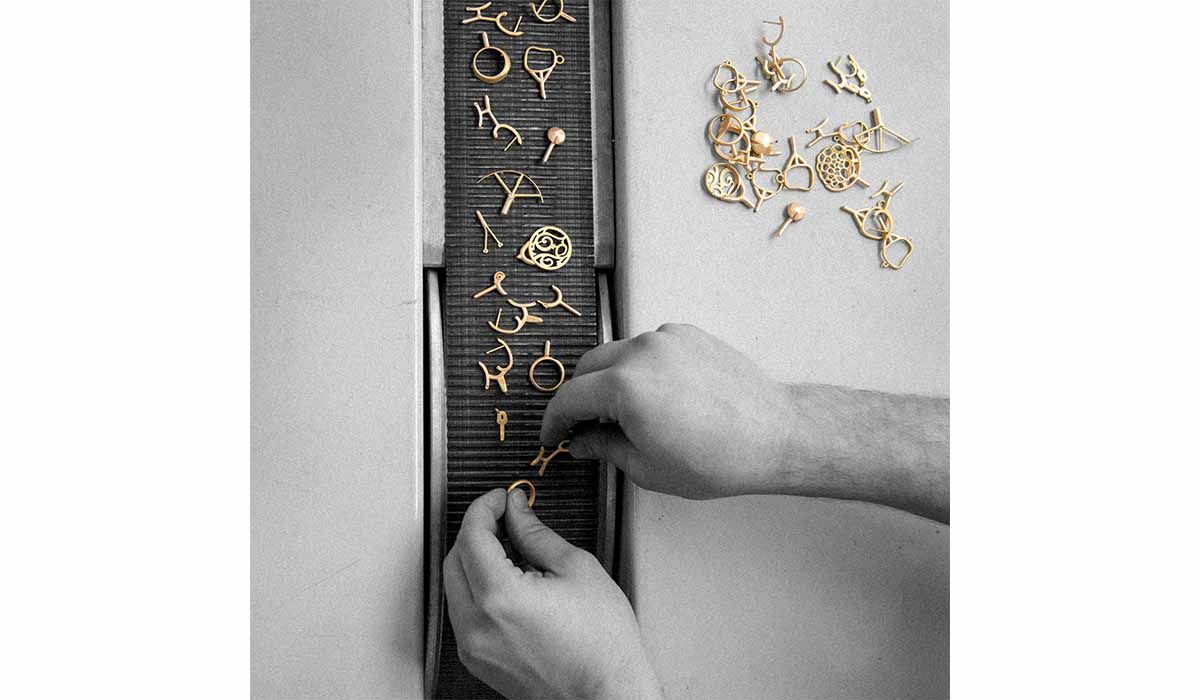

«The microfusion process is one of the most ancient methods for making objects of all kinds. Different populations and cultures have used this process to make tools, objects and statues in bronze. The Riace bronzes are one very famous example. They were found in the sea 2,500 years after they’d been cast, in Greece in about the 6th century BC. Over the centuries, the process has been developed, evolving from a simple artistic method to show exceptional versatility. While microfusion, or lost-wax fusion, is a solid process, it is not perfect. In the jewelry world, two of the most common and problematic issues are lack of fill as well as shrinkage porosity. The first issue happens with specific types of elements (filigree, certain alloys, and complex geometric shapes), but the second affects 100% of objects made this way because it is intrinsically tied to the solidification process of metal alloys. Until a few decades ago, dealing with shrinkage porosity was all about trial and error. So as to minimize this issue, getting a good result meant having to spend quite a bit of time and using more metal.

Simulating the process in a virtual environment allows for minimizing the investment, meaning less time is required and the results are better. We can say that simulation is absolutely necessary in a wide range of manufacturing sectors – in aeronautics and automotives, for example – where components need to be absolutely free of microstructural defects and where scrap can’t be reutilized. The software used in this process is from the French ESI Group, and it is called ProCAST. This is a complete and cutting-edge tool that has been on the market for more than 20 years, and it has been widely used in different industrial fields. ProCAST is able to foresee what areas of an object might have defects and the extent of them. Simulating the microfusion process is a useful tool that doesn’t completely eliminate the need for trial and error, but it limits it to the virtual environment, reducing the time and costs of industrializing a product».

Simulating the process in a virtual environment allows for minimizing the investment, meaning less time is required and the results are better. We can say that simulation is absolutely necessary in a wide range of manufacturing sectors – in aeronautics and automotives, for example – where components need to be absolutely free of microstructural defects and where scrap can’t be reutilized. The software used in this process is from the French ESI Group, and it is called ProCAST. This is a complete and cutting-edge tool that has been on the market for more than 20 years, and it has been widely used in different industrial fields. ProCAST is able to foresee what areas of an object might have defects and the extent of them. Simulating the microfusion process is a useful tool that doesn’t completely eliminate the need for trial and error, but it limits it to the virtual environment, reducing the time and costs of industrializing a product».