Due Erre, the Chain Cutting Machine Becomes Smart

Precision, versatility and intelligent process control in a single machine

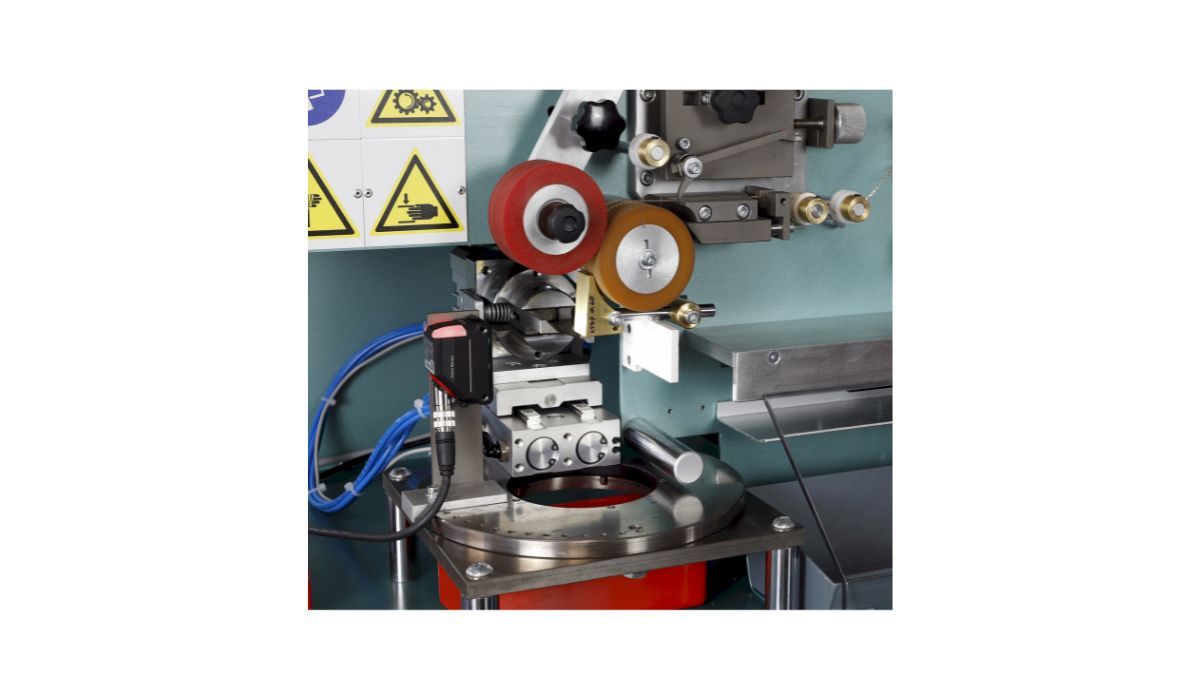

The new automatic chain cutting machine by Due Erre, a leading company in the Vicenza gold district, is an advanced solution for jewelry manufacturing due to its precision, versatility and intelligent process controlcombination. The system integrates several working modes, including length control from 5 to 750 mm, even or odd link counting via mechanical synchronization, and camera-supported optical vision cutting, which guarantees correct positioning even when links are stretched due to mechanical processing. This dual management option ensures extremely accurate counting of the number of links and significantly reduces unwanted waste, maintaining consistent quality across multiple chain types.

The machine is designed to work with rolo, ball, ball-barrel, 3+1 and 5+1 figaro chains, chains with crossbars, flu chains where a precise double cut is required to prepare the link for welding, grumetta chains, tennis chains and many more, provided that the shape of the link is well defined. For special requirements, the cutter can be rotated in relation to the chain, further increasing operational flexibility. Equipped with an automatic unwinder, safety sensors, and notebook with pre-installed management software, the machine guarantees intuitive use and high productivity, which can, for example, reach1,200 pieces per hour with a 9-link cut.It is powered by 230 V single-phase, requires 6–8 atm of air, has a power rating of 250 W, a total weight of 150 kg, and is 1200 × 600 × 1600 mm in size. It is designed for standard DIN 125 bobbins with a 12 mm bobbin holder and can cut lengths from a few millimeters up to 750 mm with the possibility of adaptations for special bobbins. An essential tool for companies that want to achieve perfect, repeatable cutswith a machine that can be adapted to the most sophisticated production requirements.