Tiffany&Co. Consolidates its Leadership in Diamond Traceability

Another step forward for Tiffany which, as of October, will disclose the entire processing cycle of its individually registered diamonds

An unprecedented step forward for the American company Tiffany&Co. regarding diamond traceability. In fact, as of October 2020, the company will be disclosing the entire processing cycle of its recent, individually registered, diamond supplies (starting from 0.18 carats). Revealing the country in which each stone is processed and mounted onto a jewelry item is a sector first that follows Tiffany’s 2019 announcement when it declared that it would be the world’s first luxury jewelry company to indicate the origin (region or country of origin) of its individually registered diamonds. By taking transparency to a new level and disclosing the entire processing cycle of its own diamonds, Tiffany strengthens the brand’s commitment to guaranteeing that every phase in the creation of its jewelry contributes to the wellbeing of the people and the planet. «Our efforts towards diamond traceability has taken another step forward today» said Anisa Kamadoli Costa, Chief Sustainability Officer for Tiffany & Co. «Our customers deserve to know that a Tiffany diamond respects the highest standards, not only in terms of quality, but also in regard to environmental and social responsibility. We believe that diamond traceability is the best way to guarantee both» she concluded.

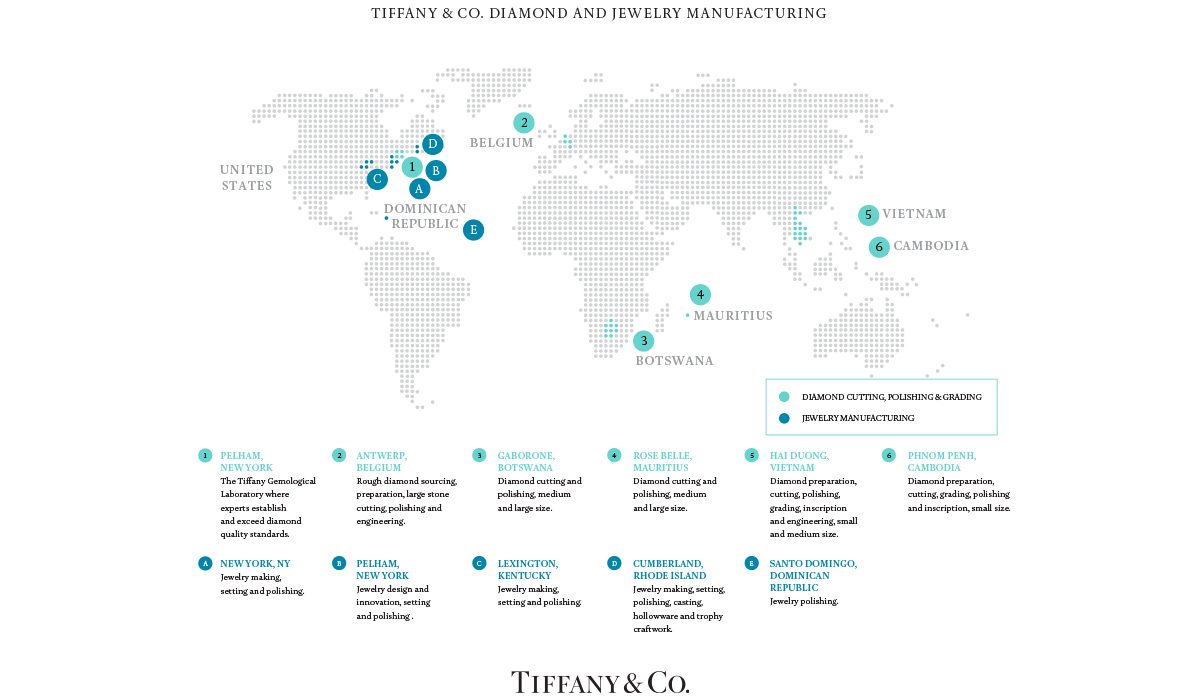

Tiffany & Co. customers will be provided with information regarding the region or country of origin, the place where the diamond was cut, polished and certified and then mounted on the jewelry item for every recent, individually registered, diamond supply. This information can be given by any Tiffany & Co. expert and will also be included in the Tiffany Diamond Certificate. Tiffany continues to be a sector pioneer by unveiling yet another passage in the diamond supply chain. Among luxury jewelry companies worldwide, Tiffany & Co. is the only brand that owns and manages five diamond processing workshops around the world. With over 1,500 artisan workers in these workshops, Tiffany ensures that the excellence of every cut is obsessively respected in order to enhance the stone’s utmost shine, dispersion and sparkle – not just its weight in carats. Thanks to these company-owned workshops in Belgium, Mauritius, Botswana, Vietnam and Cambodia, as well as Tiffany’s Gemological Laboratory in New York and five jewelry-making workshops in North America, Tiffany is able to guarantee that its own superlative standards are respected. By offering this level of supply chain transparency, something which no other luxury jewelry company in the world is able to match, makes Tiffany unique; an achievement made possible by investing in vertical integration for over 20 years. This vertical integration model not only contributes to keeping the artisan workmanship at the highest levels but also ensures premium health and safety conditions at the workplace, the economic development of the community and supply chain traceability. Together with the philanthropical activities that The Tiffany & Co. Foundation continues to conduct, donating $85M over the last 20 years, Tiffany & Co. has always been a pioneer of sustainable luxury. «Revealing the processing cycle of Tiffany diamonds reflects decades of investment in our supply chain» affirmed Andrew Hart, Senior Vice President Diamond and Jewelry Supply at Tiffany & Co. And he added: «Among luxury jewelry companies, Tiffany is the only to directly supply itself with responsibly-mined raw diamonds, which it then processes and mounts in total respect of its own standards in its own workshops.»

Tiffany & Co. customers will be provided with information regarding the region or country of origin, the place where the diamond was cut, polished and certified and then mounted on the jewelry item for every recent, individually registered, diamond supply. This information can be given by any Tiffany & Co. expert and will also be included in the Tiffany Diamond Certificate. Tiffany continues to be a sector pioneer by unveiling yet another passage in the diamond supply chain. Among luxury jewelry companies worldwide, Tiffany & Co. is the only brand that owns and manages five diamond processing workshops around the world. With over 1,500 artisan workers in these workshops, Tiffany ensures that the excellence of every cut is obsessively respected in order to enhance the stone’s utmost shine, dispersion and sparkle – not just its weight in carats. Thanks to these company-owned workshops in Belgium, Mauritius, Botswana, Vietnam and Cambodia, as well as Tiffany’s Gemological Laboratory in New York and five jewelry-making workshops in North America, Tiffany is able to guarantee that its own superlative standards are respected. By offering this level of supply chain transparency, something which no other luxury jewelry company in the world is able to match, makes Tiffany unique; an achievement made possible by investing in vertical integration for over 20 years. This vertical integration model not only contributes to keeping the artisan workmanship at the highest levels but also ensures premium health and safety conditions at the workplace, the economic development of the community and supply chain traceability. Together with the philanthropical activities that The Tiffany & Co. Foundation continues to conduct, donating $85M over the last 20 years, Tiffany & Co. has always been a pioneer of sustainable luxury. «Revealing the processing cycle of Tiffany diamonds reflects decades of investment in our supply chain» affirmed Andrew Hart, Senior Vice President Diamond and Jewelry Supply at Tiffany & Co. And he added: «Among luxury jewelry companies, Tiffany is the only to directly supply itself with responsibly-mined raw diamonds, which it then processes and mounts in total respect of its own standards in its own workshops.»