Platinum Melting Upgrade with Indutherm

MTC 100 V changes the parameters for complex jewelry design

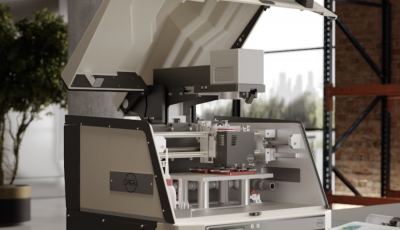

The metal casting phase in jewelry production is certainly one of the most delicate stages, especially when it comes to jewelry with complex designs. Indutherm, a leading manufacturer in the industry has developed the MTC 100 V, that sets new standards for platinum casting. Unlike conventional centrifugal casting systems, which are often prone to problems, this machine uses an innovative tilting, program-controlled casting principle with intelligent vacuum overpressure regulation, features that ensure outstanding results even for intricate designs. The MTC 100 V incorporates Indutherm's expertise in platinum processing from casting to the production and processing of platinum powder and granulate through to platinum recycling. An unparalleled solution therefore for professionals seeking precision, reliability and versatility in platinum and other jewelry metals. All Indutherm systems are equipped with induction generators, with program control and extensive interfaces according to the Industry 4.0 standard, with which each process can be analyzed and stored in detail. In addition, different user interfaces are available for control and management depending on the application.