The Laser Becomes Sustainable

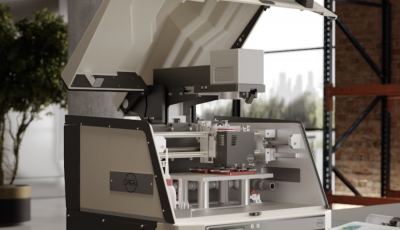

Taumac presents Tauweld Fiber, the first fiber laser with 100% Made in Italy technology and design

Some technological steps mark a before and an after. And in the world of laser welding, this is certainly the case with Tauweld Fiber, the innovative machine developed by Taumac, which to all intents and purposes represents the first fiber laser for manual welding. What makes it unique first and foremost is its durability due to its high degree of reliability and its 24 hours a day, 7 days a week usability, which means that it requires almost no routine maintenance. Added to this is an absolutely indispensable factor for those seeking high and consistent standards in the long term: Tauweld Fiber is sustainable and environmentally friendly because it consumes less than a classic welding machine - an energy saving of around 30% - and does not require constant replacement of components. It can also work on different types of metal surfaces and reacts very well on gold and silver. Moreover, designed and manufactured entirely in Italy, it is also attractive, neat and ergonomic: a 7-inch touch-screen display for quick access to parameters, 100 cells for storing work settings and air cooling are just some of its technical features. Tauweld Fiber is therefore further proof of Taumac's ability to offer the market products that are always one step ahead and able to improve working conditions and consequently the results that can be obtained on the finished product.