The new LM Industry's Chainmatic

Volume, efficiency and quality of production with the new device from Vicenza Gold District

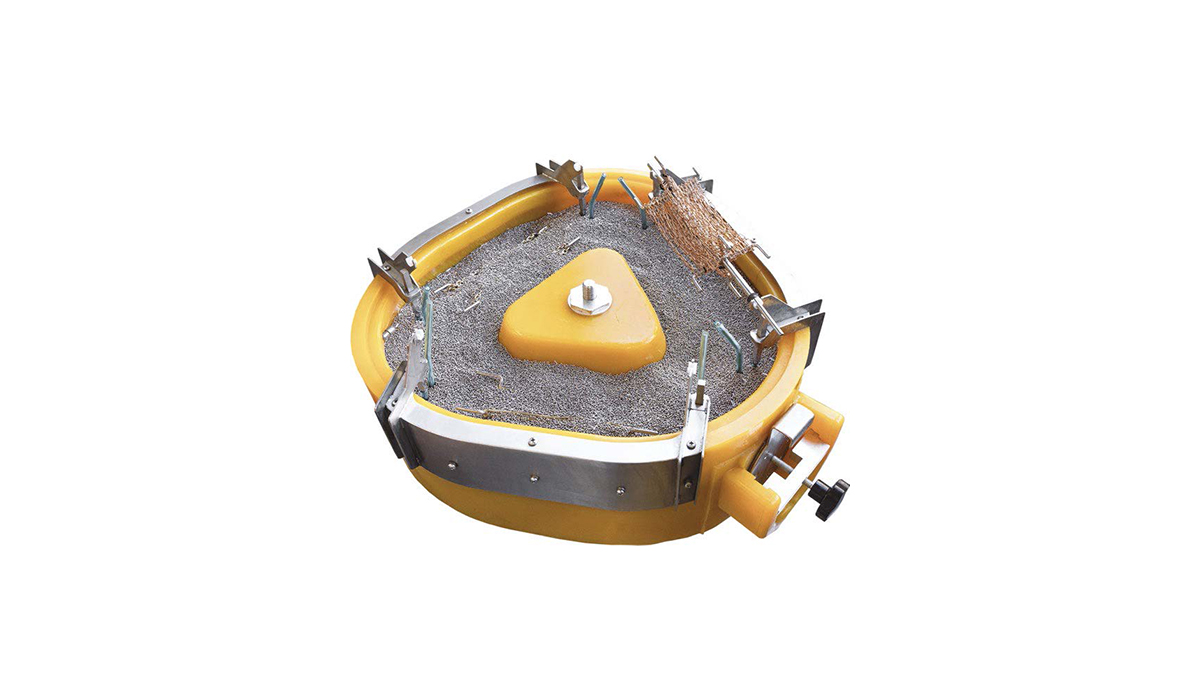

LM Industry is paying attention both to small artisan workshops and large manufacturing industries, especially with its new Chainmatic triangular vibrator. Capable of increasing volume, efficiency and quality of production, it proves the inclination towards cutting-edge products that the historical firm, based in the Vicenza Gold District, has. The concept behind the development is optimization, an objective achieved due to a series of features: the specific frames provide housing for 3 separate chain holders and can process up to 6 different types of chains at the same time; the version fitted with the very latest PLC allows for complete personalization and automation of all production parameters, from loading water and soap right through to rinsing; the raised structure of the machine contains splash and loose ball bearings, hence work areas can be kept cleaner and tidier. The new Chainmatic ensures maximum compliance in the results with specific features that prevent human error, standardizing processing and consumption over time. The installation of the new supports for the chain holders ensures the production volume of 3 rectangular vibrators combined with the machining efficiency given by the toroidal flow, typical of circular vibrators, which is created by 3 rotating points at the corners of the bath.