Nutec International: a Textbook Case “Start-up”

The Nutec International and Auroform Monolith challenge, the only electroforming machine that unites carat accuracy, automation and precious material savings, originated from the know-how and 30-years' experience of two companies, LTC Caoduro and GAB

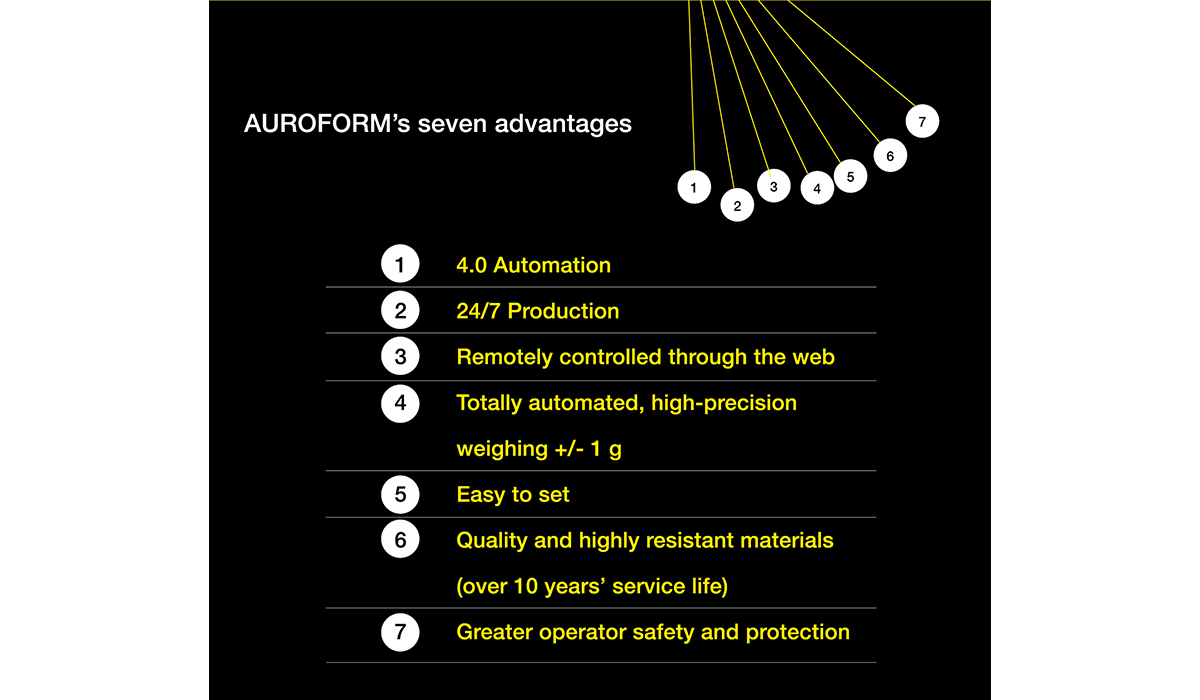

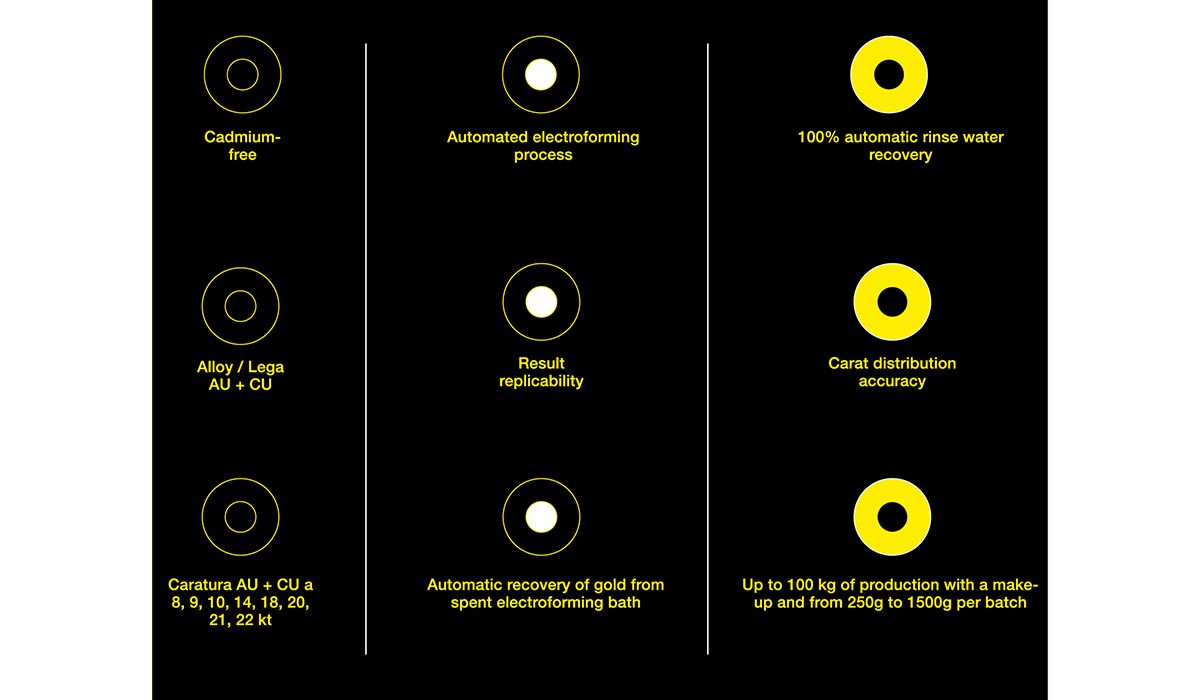

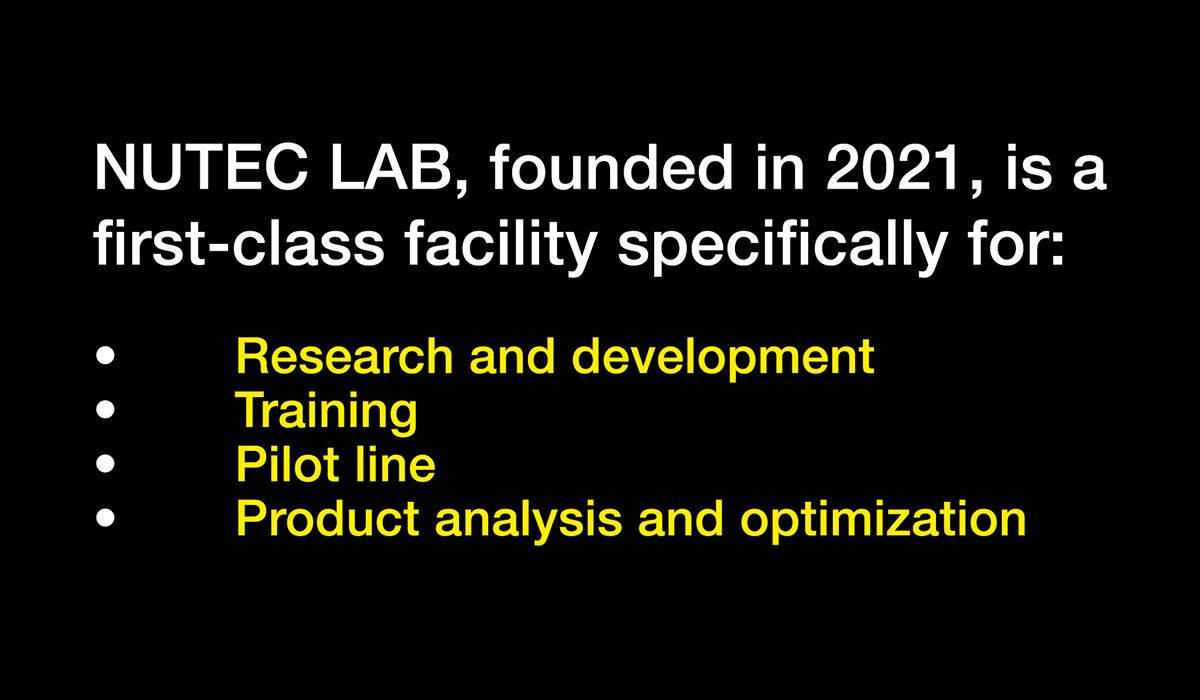

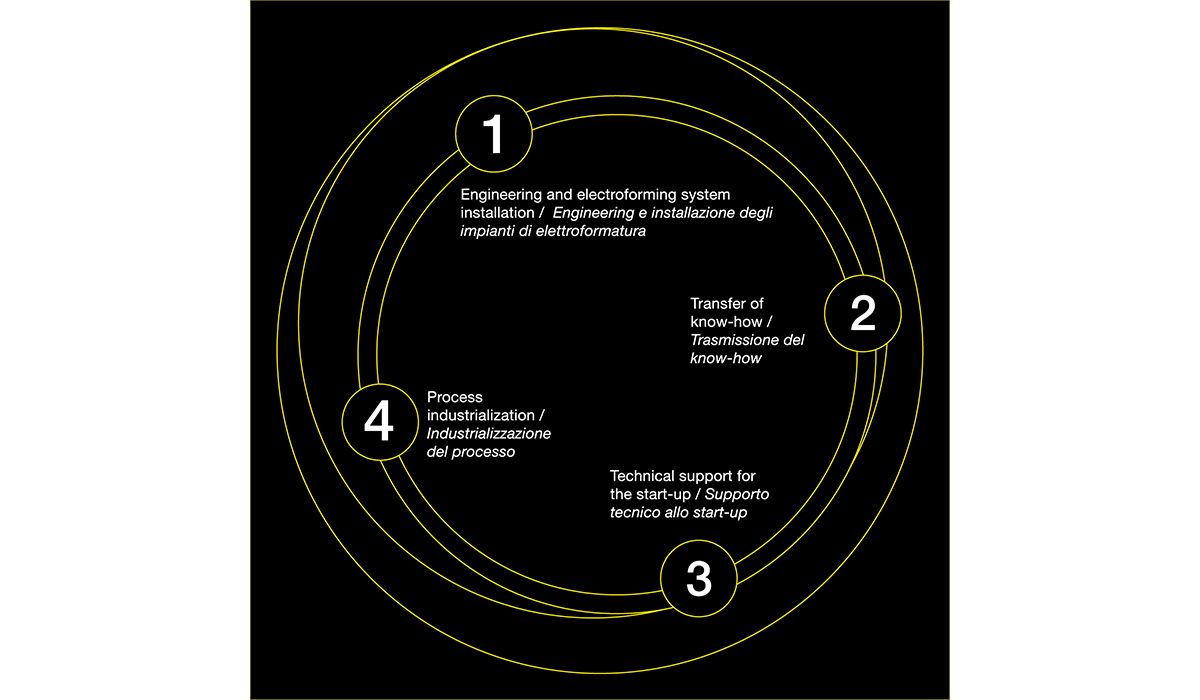

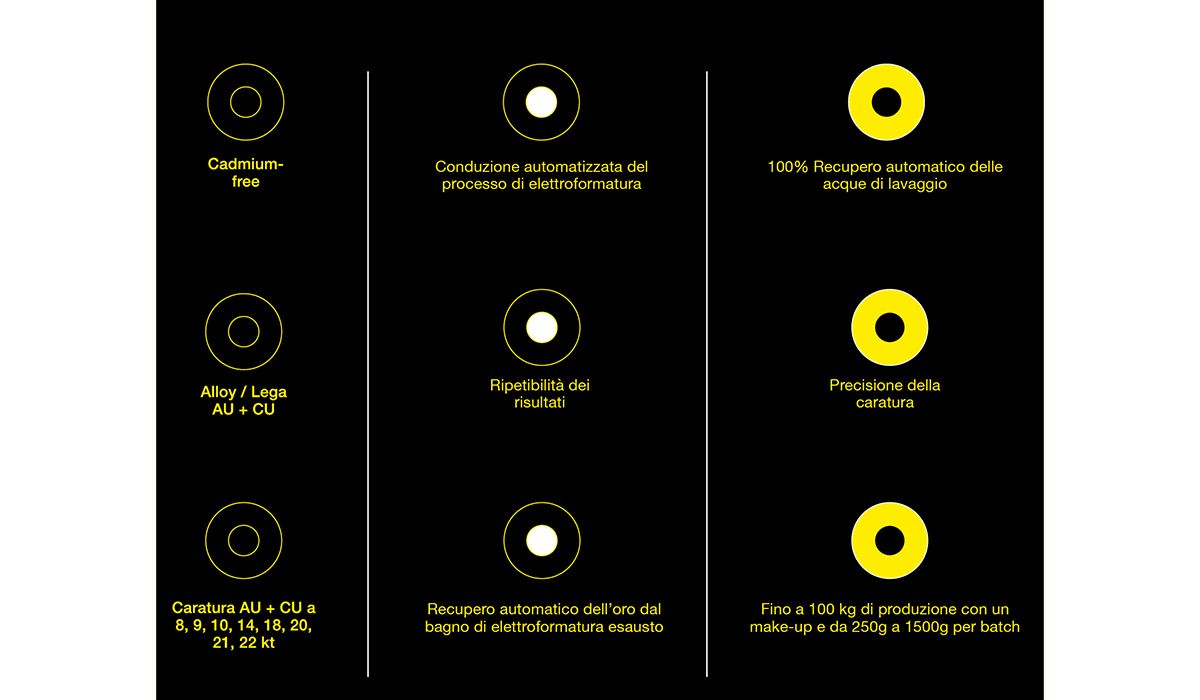

The Nutec International and Auroform Monolith challenge, the only electroforming machine that unites carat accuracy, automation and precious material savings, originated from the know-how and 30-year experience of two companies, LTC Caoduro and GAB. Nutec Lab, Nutec International’s latest endeavor, is a first-class technological facility that unites the know-how of thirty years’ experience and over thirty tons of electroformed gold jewelry produced “as an endowment” by two extremely well-established and successful companies: LTC Caoduro in Vicenza and GAB in Arezzo, which, together, founded Nutec International in 2014. As of February 2021, Auroform Monolith, the most advanced machine for mass producing articles in high-quality electroformed gold alloy, can be tested at Nutec Lab. The machine is the result of collaboration between two leading companies, one specialized in electrochemical and galvanic plating equipment and the other in electroforming. Two worlds that joined forces to find a winning solution to one of jewelry manufacturing’s biggest problems: precious metal karat accuracy. Indeed, while producing undertitled articles undermines manufacture and affects re-processing and precious metal recovery costs, over-titled production can lead to a drop in processing, weighs more heavily on production costs and is negative in terms of competition and the company’s financial balance. For this reason, producing electroformed jewelry in carat gold is a challenge that requires proven technical skills and the appropriate equipment to ensure that the process is

correctly controlled. With the internationally-patented Auroform Monolith system, this production process is now available to all companies, guaranteeing reliability, replicability and quality results, optimizing the processing drop which leads to an economic return on investment. To date, Nutec International is operative in the Middle East, North Africa and Turkey and is meeting with increasing success in Thailand, Asia and India. Countries where the chance to produce jewelry in particularly significant volumes and with carat ranging from 8 to 22 kt in gold - copper alloys, is even more attractive. And where the remaining appeal is Made in Italy excellence.

correctly controlled. With the internationally-patented Auroform Monolith system, this production process is now available to all companies, guaranteeing reliability, replicability and quality results, optimizing the processing drop which leads to an economic return on investment. To date, Nutec International is operative in the Middle East, North Africa and Turkey and is meeting with increasing success in Thailand, Asia and India. Countries where the chance to produce jewelry in particularly significant volumes and with carat ranging from 8 to 22 kt in gold - copper alloys, is even more attractive. And where the remaining appeal is Made in Italy excellence.